R & D Center

—

Introduction of R & D Center

—

The company possesses a stable design and R&D team, forming a design and R&D talent echelon with a reasonable mix of optical, mechanical, and electrical professionals, mainly composed of young and middle-aged personnel. Simultaneously, we actively collaborate with renowned domestic universities in "production, education, research, and application," working together on the R&D of high-tech products and the engineering transformation of high-tech achievements.

Hubei Hantang Intelligent Technology Co., LTD has undertaken numerous provincial innovation projects, including the online hydraulic correction equipment for commercial vehicle chassis longitudinal beams (Project No. CXG0211) and the bidirectional synchronous riveting equipment for U-section parts (Project No. CXW2015000367), etc. The company is steadily advancing technological innovation and the transformation and application of scientific research projects, thereby promoting and enhancing the automated and intelligent production level of commercial vehicle longitudinal beams and accessories.

We are at the forefront of the industry in scientific research, new product development, and the application of four new technologies. In recent years, the design center has continuously developed projects, playing a strong role in uniting the scientific and technological personnel of the design center. It also serves as a base for cultivating and training a large number of scientific and technological talents for the design center and the entire enterprise, thereby improving the quality of the company's scientific and technological personnel.

Hubei Hantang Intelligent Technology Co., LTD's R&D center is developing comprehensively, focusing on the R&D, design, and production of intelligent, integrated, and networked systems and equipment for manufacturing. We are vigorously expanding in-depth scientific research cooperation and technological development with scientific research institutions and peers in intelligent equipment, rapidly integrating and enhancing the company's R&D capabilities in customized automated/intelligent equipment. We will continue to increase investment in basic product R&D and leverage our advantages, striving to become a "high-quality supplier of domestically produced and independently controllable products," continuing to be rooted in manufacturing and continuously promoting comprehensive equipment transformation and automation upgrades.

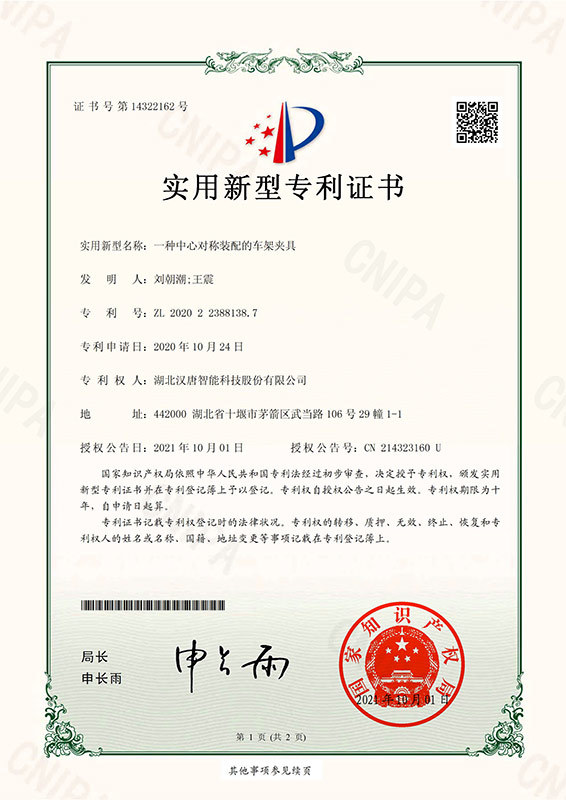

R & D Patent Certification

—

2014

◆ Component arrival detection mechanism ◆ Equipment for fixing a single-sided driven trolley running on an arc-shaped track ◆ U-shaped section part bidirectional synchronous riveting equipment ◆ Y-type centering mechanism suitable for slot-shaped section parts ◆ A rivet removal device used on commercial vehicle chassis production lines ◆ Arm-type connecting line flipping mechanism between mutually parallel conveyor lines

2015

◆ A floating locking structure for a slide device ◆ U-shaped section part bidirectional synchronous riveting equipment ◆ High-speed and efficient automatic punching production line for automotive double-layer steel beams ◆ A rear clamping conveying mechanism used in an automotive steel beam punching production line

2016

◆ Flexible chassis assembly fixture equipment ◆ Discharge slide-type quick mold change device ◆ Error prevention mechanism for concave and convex dies used in channel steel beam punching equipment

2017

◆ Commercial vehicle double-layer steel beam automatic welding production line ◆ Frame assembly line hoist automatic return system ◆ Car frame inner baffle expansion equipment ◆ Oil dipstick pressing equipment ◆ Commercial vehicle frame assembly flexible precision assembly trolley ◆ Commercial vehicle double-layer steel beam automatic spot welding production line ◆ Gearbox main shaft automatic deburring equipment ◆ Center fixed type quick clamping manipulator for forging robots ◆ Automotive steel beam production sheet batch fast turning equipment

2018

◆ Commercial vehicle double-layer steel beam automatic beam forming production line ◆ Anti-error mechanism for concave and convex mold matching in slotted steel beam punching equipment

2019

◆ A precision blanking device for a cab rear enclosure assembly

2020

◆ Assembly method for commercial vehicle balance shaft crossbeam ◆ A floating connection device suitable for servo displacement mechanisms ◆ A flexible assembly fixture for commercial vehicle balance shaft crossbeam assembly ◆ An anti-drop device for deflector hood hoisting ◆ A mechanical self-locking shaft-type part gripper suitable for automatic grasping equipment ◆ A counter-impact type bolt tightening reaction arm device ◆ A universal bolt tightening reaction arm device ◆ An assembly method for commercial vehicle balance shaft crossbeam assembly ◆ A derailment alarm device for a ground tow chain trolley

2021

◆ A water-cooled fixture for welding automotive aluminum alloy fuel tanks ◆ An auxiliary walking device for lifting the top of an orbital line body trolley ◆ A rivet removal device ◆ A nested activated carbon adsorption bed ◆ A material feeding mechanism for a commercial vehicle longitudinal beam riveting production line ◆ A longitudinal beam feeding machine ◆ A shock-absorbing track for industrial robots ◆ A chassis fixture with central symmetry assembly ◆ A positioning device for assembling the automotive front windshield ◆ A split chassis fixture based on RGV ◆ An automatic lifting device for assembling the automotive front hood

2022

◆ A shock-absorbing track for industrial robots ◆ The utility model relates to a frame fixture with center symmetrical assembly ◆ The utility model relates to an automobile front windshield assembly positioning device ◆ A split frame fixture based on RGV ◆ The utility model relates to an automatic lifting device for the assembly of an automobile front mask ◆ Medical intelligent rail car ◆ A pneumatic frame positioning pin mechanism that can be quickly replaced ◆ The utility model relates to a special spreader for automotive trough beams ◆ The utility model relates to a lifting device for commercial vehicle production line ◆ A fixture for heavy truck AGV equipment ◆ The utility model relates to a turning device for commercial vehicle production line ◆ The utility model relates to a clamping structure for commercial vehicle production line ◆ A lifting platform activity induction device ◆ The utility model relates to a position feedback device for I-steel track trolley ◆ A medical vehicle based on face recognition ◆ A medical mobile vehicle with a universal camera ◆ A medical logistics vehicle with disinfection function ◆ An intelligent mobile vehicle for carrying medical supplies ◆ A medical vehicle with extended function ◆ The utility model relates to a lifting device used for pulling a saddle shell plate stack to turn over

2023

◆ A commercial vehicle cab hoisting and anti auxiliary device ◆ A rack trolley and its ground positioning device ◆ A blunt pressing mechanism for processing the burrs at the end of the longitudinal beam holes of an automobile chassis ◆ A clamping structure suitable for multiple thicknesses of chassis longitudinal beams ◆ A device for high-precision measurement of turning angle and inclination angle ◆ A high-efficiency automatic conveyor line ◆ An automatically alignable conveyor line ◆ An auxiliary assembly trolley for new energy commercial vehicle battery packs ◆ A chassis outer width control tool

2024

◆ A crankshaft centering mechanism for automotive engines ◆ A universal bolt tightening reaction arm device ◆ Alligator beam storage rack ◆ Gun barrel beam three-dimensional storage rack ◆ A clamping mechanism ◆ A crossbeam support mechanism and device ◆ An automotive frame riveting line assembly fixture

Here is the placeholder text

Here is the placeholder text

Here is the placeholder text

Here is the placeholder text

Here is the placeholder text

Here is the placeholder text

Here is the placeholder text

Here is the placeholder text

Here is the placeholder text

Here is the placeholder text

Here is the placeholder text

Here is the placeholder text

Here is the placeholder text

Here is the placeholder text

Here is the placeholder text

Here is the placeholder text

Here is the placeholder text

Here is the placeholder text

Here is the placeholder text

Here is the placeholder text